Step-by-Step: Mesh Design and Printing Process Demystified

Step-by-Step: Mesh Design and Printing Process Demystified

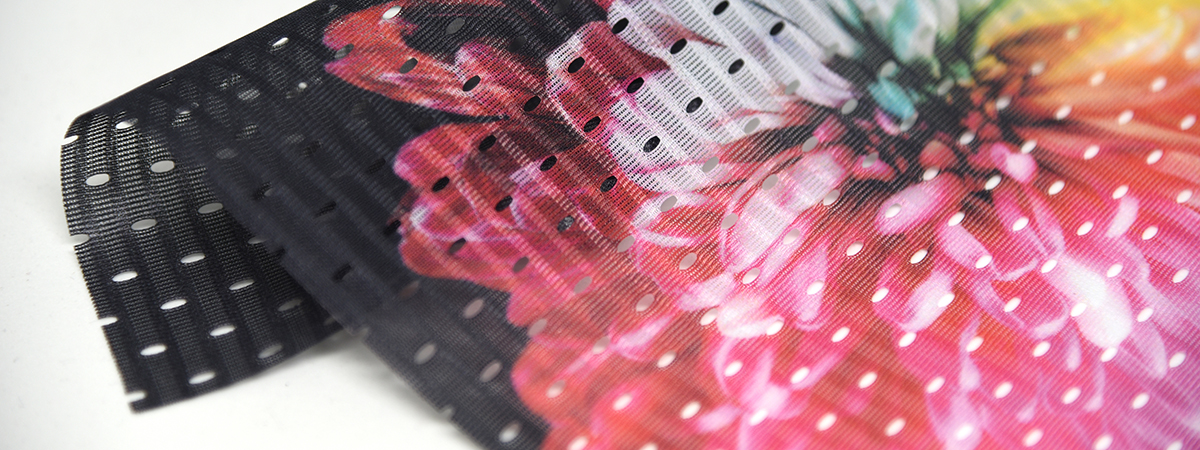

In the realm of modern manufacturing and prototyping, 3D printing has emerged as a revolutionary technology. Among the various techniques in 3D printing, mesh design plays a crucial role in creating intricate and detailed objects. In this step-by-step guide, we’ll demystify the process of mesh design and printing, providing insights into the key stages that transform digital designs into tangible objects. چاپ مش تبلیغات

Understanding Mesh Design

What is Mesh Design?

Mesh design, in the context of 3D printing, refers to the creation of a digital model composed of a network of interconnected vertices, edges, and faces. This mesh represents the geometry of the object and serves as the blueprint for the 3D printer.

Software Tools for Mesh Design

Begin the journey of mesh design by choosing the right software. Popular options include Blender, Autodesk Fusion 360, and TinkerCAD for beginners. These tools offer a user-friendly interface and a range of features for creating and manipulating 3D meshes.

Creating a 3D Model

Sketching the Idea

Before diving into the digital realm, it’s essential to have a clear vision of the object you want to create. Sketch your design on paper, considering dimensions and features. This preliminary step helps streamline the digital design process.

Digital Modeling

Once the sketch is ready, transition to the chosen 3D modeling software. Start by creating a base shape and gradually refine it. Use the software’s tools to extrude, scale, and rotate, shaping the digital model according to your initial sketch.

Fine-Tuning Details

Devote time to fine-tune the details of your model. Adjust proportions, add intricate features, and ensure that the mesh is free of imperfections. Remember that the success of the printing process depends on the accuracy and completeness of the digital model.

Mesh Optimization

Checking for Errors

Before proceeding to the printing stage, it’s crucial to ensure that the mesh is error-free. Use the software’s analysis tools to check for issues such as non-manifold geometry, holes, and overlapping faces. Addressing these problems at this stage prevents complications during printing.

Optimizing for 3D Printing

Optimize the mesh for 3D printing by refining the geometry. This includes ensuring proper thickness for structural integrity, eliminating unnecessary details that may be too fine for the printer to reproduce accurately, and orienting the model to minimize supports.

Exporting the Mesh

Choosing the Right File Format

Once the digital model is perfected, export it in a format compatible with 3D printing. Common file formats include STL (Stereolithography) and OBJ (Object). These formats encapsulate the geometry and serve as the bridge between the digital design and the physical object.

Scaling and Units

Pay attention to scaling and units during the export process. Ensure that the dimensions in the digital model align with the intended size of the physical object. This step is critical for achieving accurate and proportional prints.

Preparing for Printing

Slicing the Model

Prepare the digital model for printing by using slicing software. Slicing involves dividing the 3D model into thin layers that the printer can build sequentially. Adjust parameters such as layer height, infill density, and support structures based on the requirements of your design.

Choosing Print Settings

Selecting the right print settings is crucial for achieving the desired outcome. Factors like layer resolution, print speed, and material type influence the quality and durability of the final print. Refer to the printer and material specifications for optimal settings.

Printing the Mesh

Calibrating the 3D Printer

Before initiating the print, calibrate the 3D printer to ensure accurate layer deposition and adherence. Proper calibration prevents issues such as warping, layer misalignment, and nozzle clogging during the printing process.

Monitoring the Print

Once the printing begins, monitor the process closely. Address any unexpected issues promptly, such as filament jams or adhesion problems. Regularly check the printer’s progress to ensure that the layers are being deposited accurately.

Post-Processing

Removing Supports and Rafts

After the printing is complete, carefully remove any support structures or rafts used during the printing process. This step is crucial for revealing the true form of the printed object and requires precision to avoid damaging the intricate details.

Finishing Touches

Depending on the desired finish, additional post-processing may be required. Sanding, painting, or applying coatings can enhance the aesthetics of the printed object. Consider the intended use of the object when deciding on post-processing techniques.

Conclusion

In the journey from a conceptual idea to a tangible object, mesh design and 3D printing play pivotal roles. Understanding the step-by-step process—from sketching and digital modeling to mesh optimization and the final print—empowers creators to bring their visions to life. As technology advances, the world of 3D printing continues to evolve, providing new possibilities for innovation and creativity. With this guide, demystifying the mesh design and printing process becomes an accessible endeavor for anyone eager to explore the exciting realm of additive manufacturing.