Carbon-Fibre Reinforced Polymer (CFRP) in Construction Remediation

Carbon-fibre reinforced polymer (CFRP) has emerged as a transformative material in construction remediation, offering unparalleled strength, lightweight properties, and durability. In Australia, where diverse climatic conditions and a range of structural challenges prevail, CFRP has proven to be an invaluable resource in addressing the deterioration of infrastructure, upgrading buildings, and ensuring long-term sustainability.

What is Carbon-Fibre Reinforced Polymer?

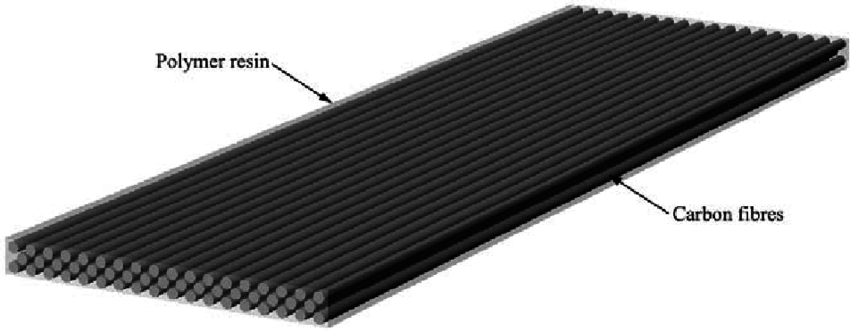

CFRP is a composite material made from carbon fibres embedded within a polymer matrix. The carbon fibres provide exceptional tensile strength and stiffness, while the polymer matrix ensures cohesion and protects the fibres from environmental damage. The combination results in a material that is lightweight, corrosion-resistant, and capable of withstanding significant loads.

Why Use CFRP in Construction Remediation?

Traditional methods of structural repair and reinforcement often involve heavy materials like steel or concrete, which can add substantial weight to an already compromised structure. CFRP, on the other hand, provides a lightweight yet robust alternative that minimises the impact on existing structures. Furthermore, its resistance to corrosion makes it particularly suitable for applications in coastal or high-humidity environments, which are common in many parts of Australia.

Key advantages of CFRP include:

- High Strength-to-Weight Ratio: CFRP is five times stronger than steel on a weight-to-weight basis.

- Durability: It is resistant to chemical and environmental degradation.

- Ease of Application: CFRP can be applied in situ without the need for heavy machinery or significant disruption to surrounding areas.

- Flexibility: It can be moulded to fit complex geometries, making it ideal for retrofitting projects.

Environmental and Economic Benefits

In addition to its performance benefits, CFRP contributes to sustainability in construction. By extending the lifespan of existing structures, CFRP reduces the need for demolition and new construction, thereby minimising waste and resource consumption. Its lightweight properties also translate to lower transportation and installation costs, offering economic advantages.

Applications of CFRP in Australia

Australia presents a unique set of challenges for construction and infrastructure, including ageing bridges, buildings, and marine structures. CFRP has been successfully employed in numerous remediation projects across the country, ensuring structural safety and extending the lifespan of critical assets.

1. Bridge Strengthening

Bridges form an essential part of Australia’s transport network, but many older bridges were not designed to accommodate modern traffic loads. CFRP has been extensively used to strengthen these structures without the need for complete replacement. For example:

- The Gateway Bridge, Queensland: This iconic bridge, which spans the Brisbane River, underwent reinforcement using CFRP strips to enhance its load-bearing capacity. The lightweight nature of CFRP allowed for the application without adding significant weight to the structure, ensuring minimal disruption to traffic.

- Richmond Bridge, Tasmania: As Australia’s oldest bridge still in use, preserving its heritage while ensuring safety was paramount. CFRP was applied to reinforce the arch structures, preserving the aesthetic and historical value of the bridge.

2. Building Retrofitting

CFRP has become a preferred material for retrofitting older buildings to meet modern safety standards, particularly in earthquake-prone areas. The material’s flexibility and ease of installation make it suitable for reinforcing walls, beams, and columns.

- Melbourne’s High-Rise Buildings: Several high-rise structures in Melbourne have utilised CFRP to strengthen their core systems, ensuring compliance with updated building codes without extensive demolition or reconstruction.

- Heritage Buildings: In Sydney, CFRP has been used to retrofit heritage-listed buildings, allowing for structural improvements while preserving the original architectural elements.

3. Marine Structures

Marine environments pose significant challenges due to constant exposure to saltwater, which accelerates the corrosion of traditional materials like steel. CFRP, with its corrosion resistance, has become a go-to solution for repairing and strengthening marine infrastructure.

- Port of Fremantle, Western Australia: CFRP was employed to reinforce the ageing piers and wharves at this busy port. The material’s durability and resistance to harsh marine conditions ensured a long-term solution with minimal maintenance requirements.

- Darwin Waterfront: CFRP was used to rehabilitate the waterfront structures, ensuring resilience against both saltwater corrosion and the tropical cyclone conditions prevalent in the Northern Territory.

4. Road Infrastructure

Australia’s vast road network relies on durable infrastructure, but ageing culverts and retaining walls often require remediation. CFRP has been used to repair and strengthen these structures efficiently.

- Hume Highway, New South Wales: Several culverts along this major highway were rehabilitated using CFRP to ensure continued safety and functionality. The lightweight nature of CFRP allowed for quick application, minimising disruptions to traffic.

What’s Next for CFRP?

As Australia continues to grapple with the challenges of ageing infrastructure and climate change, the role of CFRP in construction remediation is likely to expand. Advances in manufacturing technologies are expected to reduce costs, making CFRP more accessible for a wider range of projects. Moreover, ongoing research into hybrid composites and sustainable resins will enhance the material’s environmental credentials.

Key areas of growth include:

- Seismic Retrofitting: With increasing awareness of earthquake risks, particularly in regions like Adelaide, CFRP is poised to become a standard solution for seismic upgrades.

- Renewable Energy Infrastructure: CFRP’s lightweight and durable properties make it suitable for wind turbine components and solar panel support structures.

- Sustainable Housing: The material’s potential in modular and prefabricated construction could revolutionise the housing industry.

Carbon-fibre reinforced polymer has revolutionised construction remediation, offering a versatile, durable, and sustainable solution to Australia’s infrastructure challenges. Its successful application in bridge strengthening, building retrofitting, marine structures, and road infrastructure highlights its adaptability and effectiveness. As technology advances and costs decrease, CFRP is set to play an even more significant role in ensuring the safety and longevity of Australia’s built environment.